Prefabricated production and warehouse halls are becoming an increasingly popular choice among entrepreneurs seeking efficient, cost-effective, and fast construction solutions. Choosing this type of structure offers numerous benefits that can significantly impact the growth of your business. Discover why it is worth investing in prefabricated production and warehouse halls.

SYSTEM PEKABEX® HALLS

Pekabex System® is a comprehensive solution for the industrial and logistics sectors, providing space optimization and volume reduction of buildings while maintaining interior ergonomics. The prefabricated reinforced concrete structure guarantees durability, flexibility, and natural fire resistance, allowing for future adaptability. Precisely manufactured prefabricated elements ensure high efficiency and safety in modern production halls, while the concrete’s resistance to extreme conditions enhances worker safety. The Pekabex® system, used in projects such as production and warehouse halls, stands out for its efficiency, enabling the integration of internal installations.

PEKABEX® SYSTEM EFFICIENCY

Why is the Pekabex® System the best choice? Because it offers additional advantages:

- Increased usable space due to reduced roof element dimensions by prestressing the reinforced concrete structure.

- Reduced overall building volume while maintaining the lowest possible internal clearance.

- Distribution of key installations, such as gas, water, vacuum drainage, or compressed air, through specially prepared openings in beams and exchanges.

PEKABEX® SYSTEM DURABILITY

A well-selected, designed, and constructed structure is an investment for years to come. A thoughtfully planned framework also allows for the future adaptation of the building to new functions. Reinforced concrete guarantees lower operating costs and natural fire resistance.

PEKABEX® SYSTEM SAFETY

Prefabrication allows for precise design of elements tailored to specific loads and conditions, enhancing the safety and efficiency of the structure. Concrete is a highly durable material that performs well under dynamic loads, such as heavy rainfall. It withstands elastic deformations and large loads without permanent damage.

Prefabricated reinforced concrete structures have significantly greater resistance to high temperatures compared to other construction materials, such as steel. In the event of a fire in a production hall, prefabricated reinforced concrete elements can maintain their load-bearing capacity for a longer time than steel, giving workers and firefighters more time for evacuation and rescue operations. Additionally, concrete does not burn, reducing the risk of fire spreading further in the production hall.

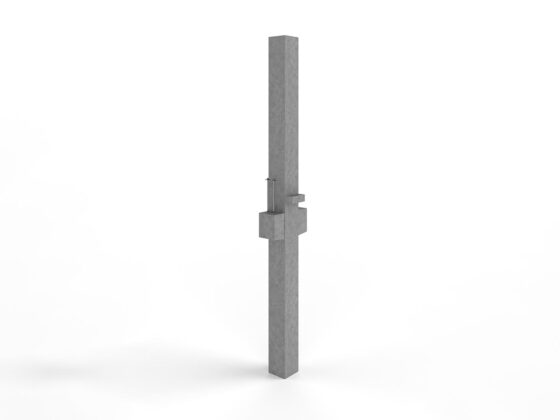

Columns

We manufacture reinforced and prestressed concrete columns.

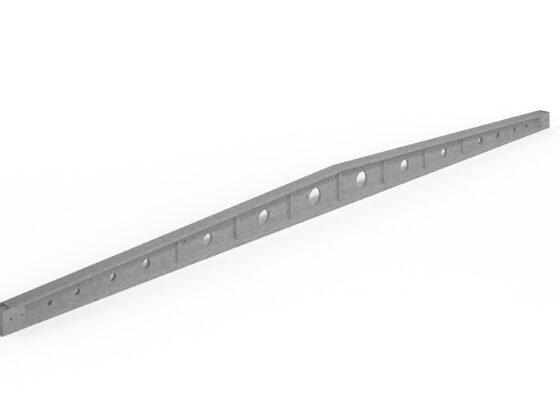

Girders

We offer prestressed roof girders of the following types:

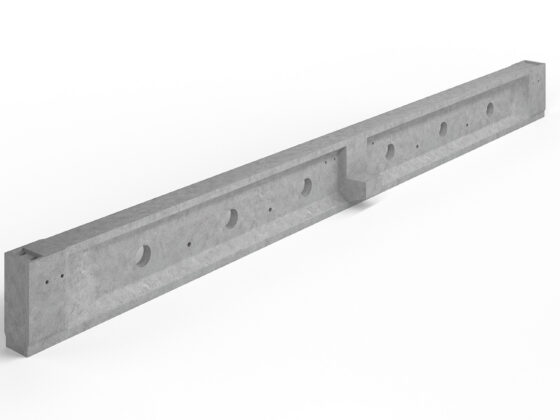

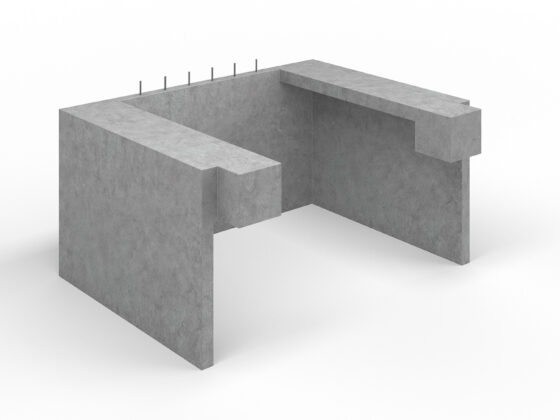

Trimmer bars

We offer prefabricated reinforced or prestressed concrete replacements. The most commonly used cross-sections are constant height I-beams of type IW or rectangular sections. The replacements include the necessary brackets for supporting the girders, as well as accessories for installation, for example.

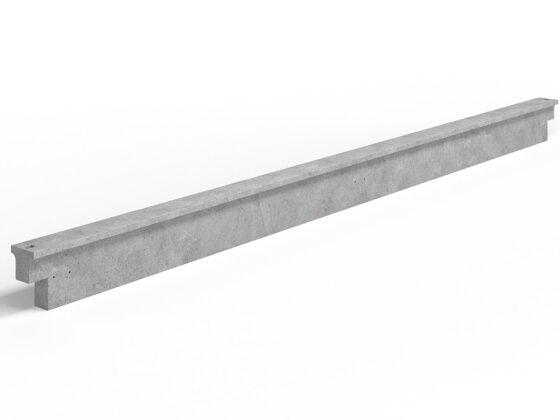

Purlins

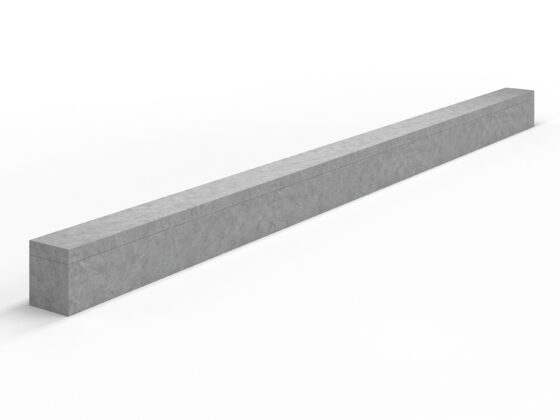

Beams

Prefabricated reinforced concrete beams, both reinforced with bars and prestressed. Typical cross-sections include rectangular, square, and shapes resembling an inverted T or L. Dimensions and design solutions are selected individually, according to the client’s requirements and the project.

Schody

Wykonujemy elementy klatek schodowych, w tym prefabrykowane biegi schodowe gotowe do zainstalowania wprost na budowie, bez konieczności wykonywania dodatkowych prac monolitycznych. Produkujemy biegi i spoczniki schodowe w systemie jedno- dwu- oraz trójbiegowym, według indywidualnych wymiarów projektu.

Docks

Prefabricated docks are primarily used in logistics and storage halls. We produce them as spatial elements and single units for integration. These elements can be made as standard or customized for specific types of gates and loading ramps.

Walls

Single-layer, double-layer, triple-layer, or maybe composite walls? Prefabricates can have any shapes, dimensions, and window and door openings.

TT Slabs

TT slabs are characterized by ribs spaced 1.2 meters apart and a smooth underside from the formwork. TT slabs are designed for creating ceilings that support heavy loads and significant spans, allowing for a reduction in intermediate columns. Rib heights range from 40 to 90 cm. TT slabs can be reinforced or prestressed.

HC and HM pre-stressed hollow core floors

The panels allow quick and efficient installation on site, without the need for scaffolding, formwork and temporary supports.

Spoilers

We manufacture staircase components, including prefabricated stair treads ready to be installed directly on site, without the need for additional monolithic work. We manufacture stair runners and treads in one-, two- and three-run systems, according to individual project dimensions.

Foundations

Prefabricated foundations help avoid time-consuming monolithic work on site. To minimize construction time, we offer prefabricated foundations, such as bell-shaped footings or pedestal footings, which consist of a column with a foundation base. Dimensions and design solutions are selected individually according to the client’s requirements and the project.

Do you have any questions?

Małgorzata

Gawrońska

Regional Director

North

+48 661 351 733

malgorzata.gawronska@pekabex.com