#offer

Pekabex is the largest producer of structural prefabricated reinforced concrete elements for modern system construction in Poland. For over 50 years, we have been providing innovative solutions in the design, production, and assembly of prefabricated building structures. We take pride in our experience and expertise, which enable us to deliver the highest quality concrete prefabricates. Our products are used in various sectors of construction, including both building and engineering projects.

At Pekabex, we produce both traditionally reinforced concrete elements and modern prestressed concrete components. Our concrete prefabricates are used in various types of construction – production and warehouse halls, residential buildings, service and public buildings, as well as road and bridge infrastructure. Thanks to our innovative solutions, prefabricated construction has become synonymous with quality, efficiency, and modernity. Prefabrication shortens project completion times and optimizes costs, making it an ideal choice for contemporary construction projects.

Prefabrication – a guarantee of quality and aesthetics

We focus on both the technical aspects of our products and the architectural and aesthetic qualities of the finished structures. Our prefabricated elements are not only durable and functional but also aesthetically aligned with different architectural styles. Whether you’re planning the construction of a residential, industrial, or engineering project, Pekabex is ready to deliver solutions that meet your expectations.

factories

contracts per year

number of employees

heaviest element

longest element

designers

#production

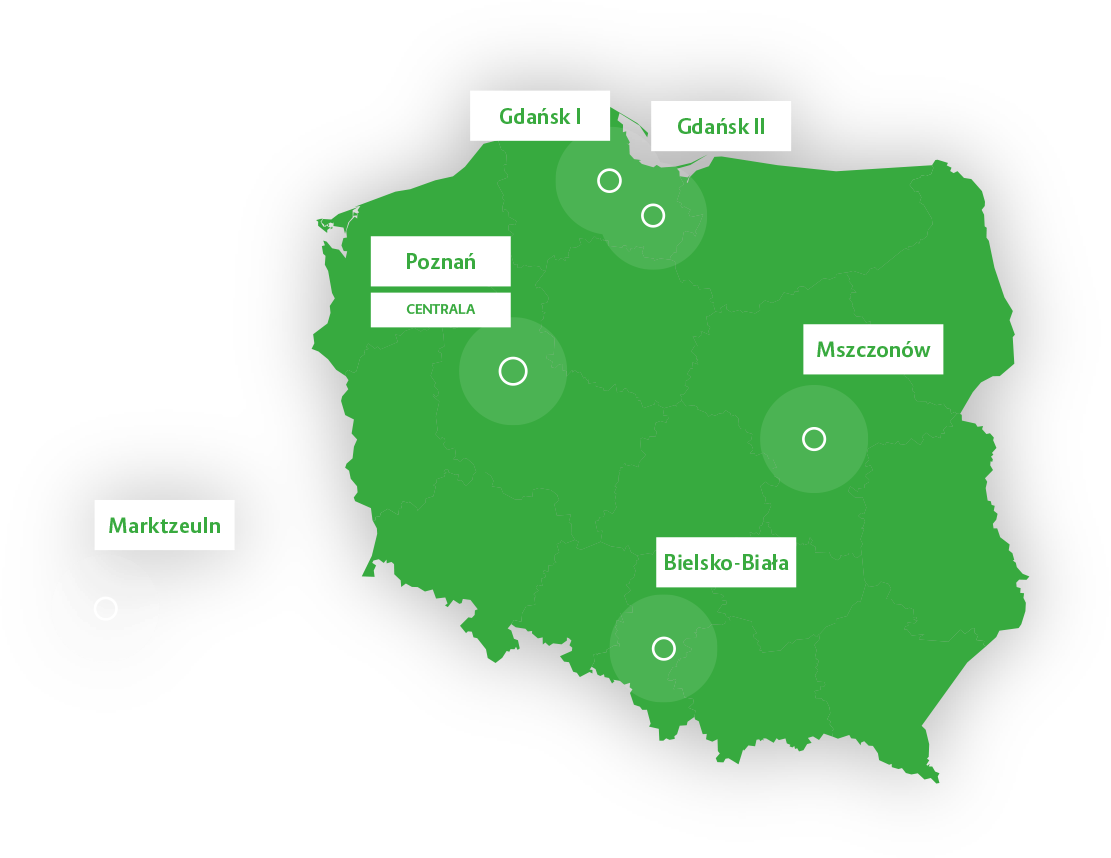

Production of prefabricated elements is carried out at 6 plants. Their strategic location enables efficient logistics of products not only in Poland, but also abroad: mainly in Germany, Denmark and Sweden. The total production capacity of all our factories at about 300 thousand m3 annually provide great opportunities and allow the implementation of the largest projects in the region.

#design

Our comprehensive technical consulting, concept development, and project execution for structural designs at every stage of an investment process ensure an optimal final product and added value for the Client. We enhance design methods by working with BIM technology.

- Identifying the Client’s needs and preferences

- Conceptual work

- Building, technical, execution, and workshop designs

Optimization and Design Improvements At every stage of the design process, we evaluate possible alternatives and propose the latest technical solutions to optimize costs and reduce the environmental impact of the investment, for example, by minimizing the amount of concrete or steel used.

#transport

The Logistics Department ensures that all concrete prefabricates leaving our factories each week are transported to construction sites efficiently and safely.

Before delivering prefabricated structures, our specialist visits the construction site to verify transport conditions.

Due to the size and weight of the prefabricates, we use specialized vehicles and trailers and obtain dedicated permits for oversized transport. We have the capacity to transport loads over 40 meters in length, up to 4.5 meters in height, and exceeding 80 tons in weight.

We collaborate exclusively with carriers that operate fleets meeting Euro 5 and Euro 6 emission standards.

#assembly

Specialized assembly teams quickly and professionally erect prefabricated structures, handing over the site for the next stages of work. With more than 20 of our own assembly teams, we are equipped to tackle even the most challenging projects, ensuring timely completion of investments. We also have our own equipment base, including mobile cranes with a lifting capacity of up to 200 tons. To maintain the highest quality, our surveyors continuously verify the positioning of prefabricated elements during the assembly process.

We prioritize the safety of our assembly workers and others present on the construction site by providing high-quality equipment and conducting regular health and safety (BHP) training to minimize risks.

Full synchronization between production, transport, and assembly allows for direct installation from the transport vehicle without the need for on-site storage of elements, even during the winter season. Prefabrication is the future of construction.

SALES DEPARTMENT

PREFABRICATION

+48 605 557 819

+48 61 821 04 41

Request for proposals:: oferty@pekabex.com

Technical Consulting

doradca.techniczny@pekabex.com

SALES DEPARTMENT

RESIDENTIAL PROJECTS

Natalia Rajewska

+48 661 380 131

natalia.rajewska@pekabex.com